Improve your FPSO operational efficiency and lower costs by benchmarking your assets against the world’s top performers.

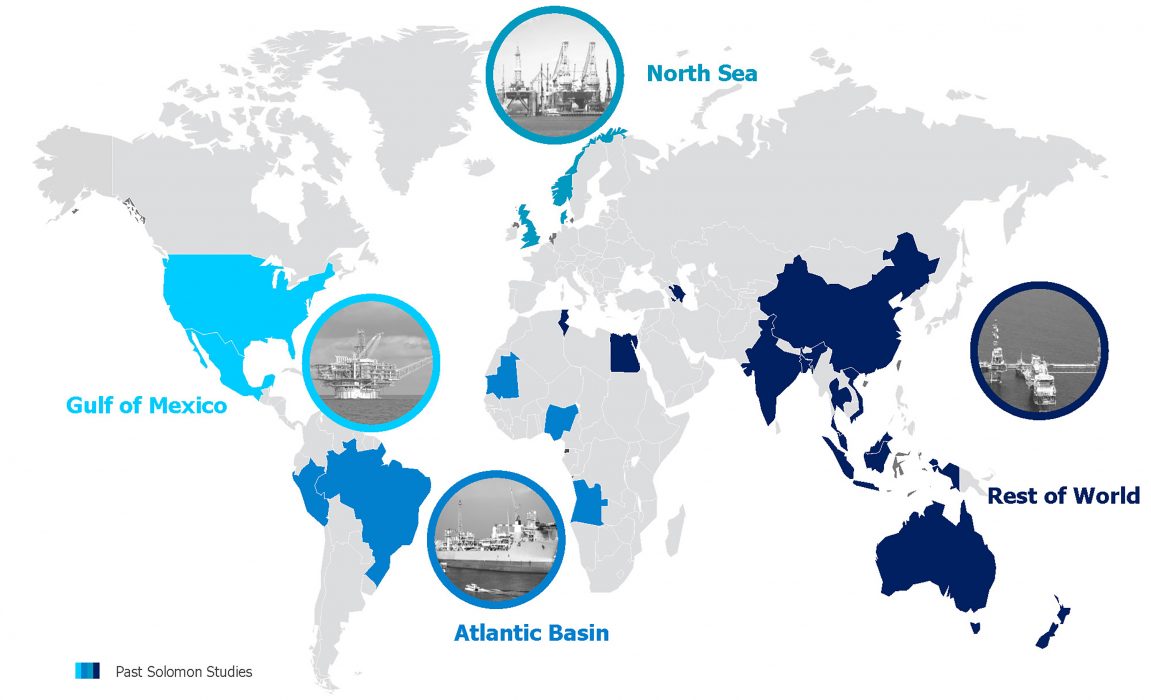

Solomon’s International FPSO Operations Efficiency Analysis (FPSO Study) evaluates operating costs and uptime reliability for FPSO (floating, producing, storing, and offloading) vessels, assessing a diverse mix of operators located in various regions worldwide.

The reliability metrics used in the study, first developed as part of Solomon’s Worldwide Offshore Production Operations Performance Analysis (Offshore Study), is continuously enhanced with input from our clients. Metrics include the value of lost oil production, Mean Time Between Incidents (MTBI), and Mean Time To Recover (MTTR). Uptime is a prime driver of upstream “value-add,” as the value of production lost to downtime far exceeds that of operating expenses (OpEx). The FPSO Study focuses on OpEx, production uptime reliability, and operating efficiency.

Study participants receive best-in-class production uptime targets that help to justify and confirm the value of future investment decisions aimed at improving reliability. Participants also receive confidential, blinded, asset-level comparisons identifying potential savings in each cost category, as well as detailed cost-driver analysis. For every study participant, Solomon identifies the best areas for pursuing efficiency savings, enhanced reliability, and increased production.

Learn How You Can Participate

Obtain a clear picture of your competitive position with data-driven, actionable insight. Make informed decisions and justify your strategies and improvement projects.

Solomon has operations data for

>90

FPSO vessels worldwide.

Study Benefits

Get answers to questions key to your success:

- How reliable is my FPSO performance?

- How does my equipment utilization compare with that of others?

- Are my operating expenses comparable to those of operators with similar facilities?

- Do my facilities deliver a competitive OpEx, accounting for my utilization and complexity?

- How do I compare across the range of performance in the industry?

Data Quality, Benchmarking Methodology

A Foundation for Effective Comparative Performance Analysis and Decision Support

We prioritize the integrity and confidentiality of participant-submitted data and rigorously review that data before benchmarking begins. Then, we employ our normalization process and benchmarking methodology to provide valuable and trusted peer group comparisons that deliver meaningful KPIs. Finally, our staff of senior consultants apply their deep industry experience to develop practical insight and recommendations to enable your success.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)