Capture Large, Operational Cost Savings & Maximize Operational Uptime in Your Thermal Oilsands Project

While production from thermal in situ oilsands projects will grow, margins remain under pressure. To stay competitive, operators must understand what drives good operating performance and how to improve steam and production operations.

Solomon’s Worldwide Production Operations Performance Analysis (Onshore Study) offers a specilized, custom thermal oilsands peer group that uses proprietary data to provide an additional, more detailed comparison of your thermal oilsands projects against other oilsands operators. To uncover key areas of underperformance in your oilsands operations, the peer group comparison uses a root-cause analysis to identify quick and direct solutions to reduce costs and maximize production

"We are pleased with your work…a statistically rigorous analysis coupled with real suggestions that can be used to improve operating performance” Development Manager, Large Independent Producer

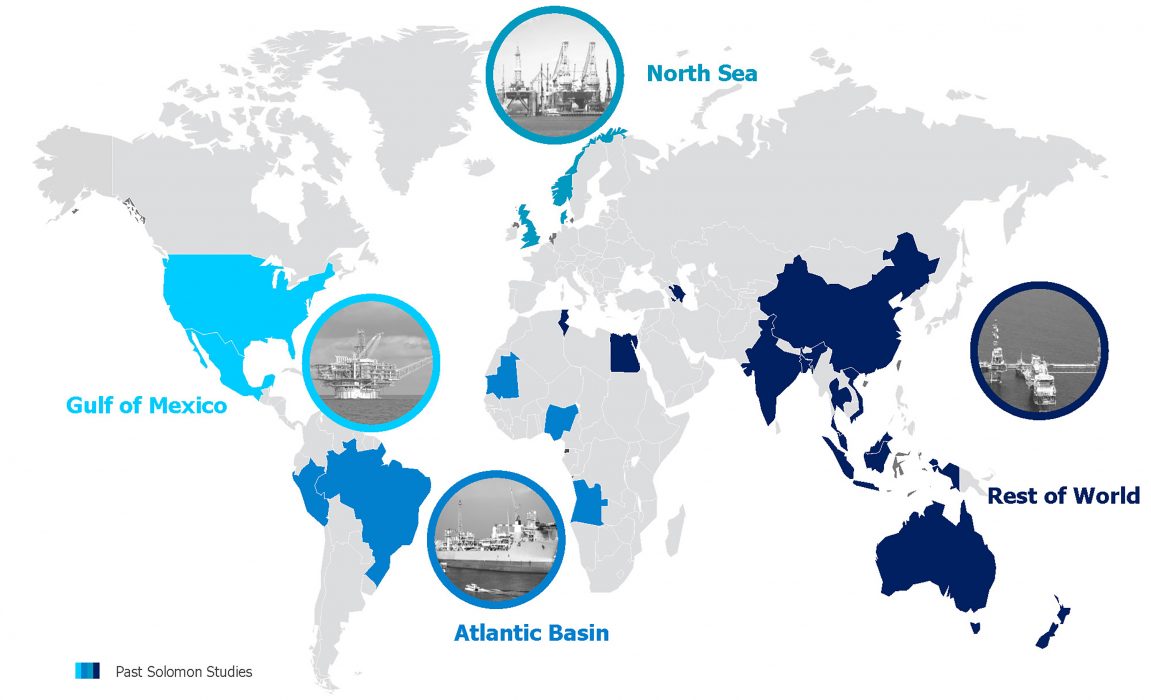

Leverage a vetted, proprietary performance database of: >3,700 onshore production and processing facilities from 40+ countries, including the major production hubs such as, US Shale, Western Canada, the Middle East, Southeast Asia, and Australia.

- How reliable are my facilities?

- How does my equipment utilization compare with that of others?

- Are my operating expenses comparable to those of companies with similar facilities?

- Do my facilities produce a competitive gross margin, accounting for my utilization and complexity?

- How do I compare across the range of performance in the industry?

To optimize your savings opportunities, the thermal oilsands Onshore Study custom peer group focuses on two main areas, uptime and cost. The uptime reliability analysis asseses the production efficiency of your project’s deferred revenue, and identifies production and steam plant reliability improvement targets (Figure 1). The cost analysis compares the total unit operating costs to peers and provides an in-depth analysis of your production and plant operations by cost category (Figure 2).

Figure 1. Uptime Reliability Performance

Figure 2. Unit Cost Categories

Solomon's categories of key controllable costs help reconcile complex problems into three main areas: steam plant, energy use, and field operations. Once the problem is categorized, Solomon investigates deeper into subclassifications to focus on specific cost opportunities.

Why Participate?

- Identify quick and direct cost reduction opportunities

- Set production improvement targets

- Understand how your total unit operating costs compare to peers

- Maximize operational uptime and production

- Find solutions to problem areas in steam plant, energy use, and field operations

Custom Peer Group Study Deliverables

In addition to all Onshore Study analyses and deliverables, peer group participants receive the following:

- Customized oilsands diagnostic analysis targeting each project and cost category

- Data collection support

- Executive summary results presentation

- Private debriefings with staff/field personnel

New Metrics that Support Emissions Strategies

Several new methodologies have been added to improve onshore operations cost and reduce emissions, including:

- Energy Intensity Index™ (EII®)

- Carbon Emissions Index (CEI)

- Operations Delivery Index

Frequently Asked Questions (FAQ)

A: Solomon’s Worldwide Production Operations Performance Analysis (Onshore Study) uses proprietary Comparative Performance AnalysisTM (CPATM) methodologies and key performance indicators to compare and assess the operational performance of onshore operators relative to peers to enhance operations performance in the medium- and long-term. The specilized, custom thermal oilsands peer group uses the proprietary data from the Onshore Study to provide a more detailed comparison of your thermal oilsands projects against other oilsands operators.

A: A custom peer group allows you to move beyond standard broad peer groups and create comparisons personalized to your unique situation needs, tactics, and strategic plans to improve your company’s competitive performance. Peer groups can be customized based on geography, operating region, size, complexity, or configurations.

A: With the custom oilsands Onshore Study peer group, you will receive the same study details and performance analysis, as with a standard peer group analysis, but will also receive a more detailed performance comparison in your operating region. The thermal oilsands peer group uses the Onshore Study’s comparative performance analysis methodology and proprietary data to provide a detailed comparison of thermal oilsands projects’ steam plant, energy use, and field operations against other thermal oilsands operators. This benchmarking analysis uncovers key areas of underperformance, enabling root-cause analysis to identify appropriate quick and direct solutions to optimize/reduce costs and maximize production.

A: Solomon’s thermal oilsands custom peer group analyzes cost by comparing the total unit operating costs to peers to provide an in-depth analysis of your production and plant operations by cost category. This detailed analysis identifies excessive expenses and savings potential for each important cost category for every project.

A: Solomon’s thermal oilsands custom peer group analyzes uptime reliability by assessing the production efficiency of your project’s deferred revenue, the frequency and impact of incidents, the Reliability Index (RI) ratio of the duration to the time to recover from incidents and turnaround metrics. This detailed analysis identifies production and steam plant reliability improvement targets to maximize production and uptime.

Learn How You Can Participate

As key information is not always readily available, it is often not easy to determine which operating areas offer the greatest potential for meaningful savings and whether operations are at maximum uptime. Join others that leverage the Onshore Study’s thermal oilsands custom peer group to maximize production and uptime, identify excessive expenses, and discover savings potential for each important cost category for every project.

Data Quality, Benchmarking Methodology

A Foundation for Effective Comparative Performance Analysis and Decision Support

We prioritize the integrity and confidentiality of participant-submitted data and rigorously review that data before benchmarking begins. Then, we employ our normalization process and benchmarking methodology to provide valuable and trusted peer group comparisons that deliver meaningful KPIs. Finally, our staff of senior consultants apply their deep industry experience to develop practical insight and recommendations to enable your success.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)